08/26/2023 11:20

Unlike many traditional business models, Mercury Wire believes that adding value goes well beyond the typical transactional exchange of goods explains Robert Yard, President, Mercury Wire. “Adding value starts well before a product is made – our process begins with thoroughly understanding customer needs and then aligning our operations to […]

Read more ›

08/15/2023 13:58

Companies that know manufacturing know lean is the way to go. But even lean operations might have some work to do if they’re not using the right tools. As far as advanced technology goes in the manufacturing sector, RFID is actually pretty simple. For just pennies each, radio frequency identification […]

Read more ›

07/08/2023 9:23

Norman Bodek began exploring the notion of productivity in the 1970s. As he pored more deeply into the topic, and how it affected manufacturing, he found himself increasingly analyzing ideas that were born overseas. Along the way, he became one of the first Americans to write about “lean manufacturing, the […]

Read more ›

06/05/2023 14:49

While manufacturers have used lean principles for decades to increase their productivity and reduce complexity, smart technologies can now be integrated to enhance the impact. Daniel Küpper, partner and managing director at the operations and industrial goods practice at Boston Consulting Group, told BCG.com that manufacturers seeking to optimize their […]

Read more ›

05/13/2023 9:43

Energy efficiency is good for profitability and the planet. What’s more, simple improvements in resource management can produce big benefits Of all the commercial factors that might motivate a firm to play its part in the fight against climate change, the chance to improve its efficiency offers the most potential […]

Read more ›

05/05/2023 10:42

A warehouse worker using an augmented reality wearable device. By now, it’s well known and widely accepted that the explosive growth of e-commerce over the last five years has seriously disrupted the logistics and supply chain industries. Consumers expect fast, cheap (or even free) shipping, a wide range of choices, […]

Read more ›

04/05/2023 10:29

There are at least three major unrecognized advantages of instituting lean principles, including better navigating the competitive life cycle. In practice, lean manufacturing is an operating philosophy that yields a number of long-term benefits that aren’t always obvious to those who are considering adopting it. The first thing most manufacturing […]

Read more ›

03/11/2023 15:48

Are you in danger of signing up for more than you can resource? Here’s expert advice on how to prevent “death by a thousand initiatives.” Question for Ask the Expert: Lean Leadership: In one of your early columns, you wrote: “This is one of the biggest mistakes that […]

Read more ›

07/11/2022 15:32

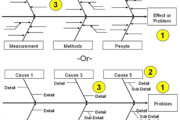

The 7 wastes are activities identified in an organization that do not add value but cost money. It is estimated that only 5% of our time actually adds value to the customer; if this indeed is true, it means that every company can learn from the 7 wastes to cut out wasteful processes and increase the percentage of value […]

Read more ›

06/02/2022 14:45

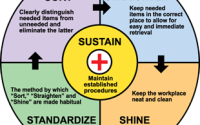

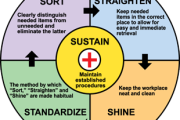

At UGN, one of our core operating principles is sustainability. That means minimizing waste to improve efficiency, add value, and refine the manufacturing process for our automotive products when and where we can. Lean manufacturing methodology is still considered a best practice in automotive manufacturing circles, despite increased Industry 4.0 […]

Read more ›

News, training, experts opinion, bibliography, software and everything about Lean world.

News, training, experts opinion, bibliography, software and everything about Lean world.